Hub motors dominate e-bike conversion markets, but understanding that "hub motor" encompasses two fundamentally different technologies—geared hub motors and direct-drive hub motors—proves essential for selecting optimal systems matching your specific riding needs, performance expectations, and budget constraints.

While the best ebike kit category includes both motor types, their distinct operating principles, efficiency characteristics, power delivery, noise profiles, maintenance requirements, and ideal applications make one type significantly better than the other for specific riding scenarios despite both motors sharing the basic hub-motor architecture of mounting within the bicycle wheel rather than at the bottom bracket like mid-drive systems.

Geared Hub Motors Explained

How Geared Hub Motors Work

Internal Planetary Gearing:

Geared hub motors contain small electric motors spinning at high RPM (typically 3000-5000 RPM) with internal planetary gear reduction systems converting high motor speed into lower wheel speed with increased torque—conceptually similar to automobile transmissions converting high-RPM engine speed into appropriate wheel rotation speeds through gearing multiplication.

Key Components:

- High-RPM brushless motor (compact, lightweight)

- Planetary gear reduction (typically 5:1 to 7:1 ratio)

- Freewheel mechanism (motor disengages when not powered)

- Nylon internal gears (quiet operation, efficient)

- Sealed bearings (weather protection)

Operating Principle:

Motor spins 3000+ RPM → Internal gears reduce to 500-700 RPM → Appropriate wheel speed achieved → High torque delivered through gear multiplication → Lightweight compact motor provides adequate power

Geared Hub Motor Advantages

Lightweight Construction:

Internal gearing enables smaller motors delivering adequate power:

- Weight: 2.7-4.5kg typical (significantly lighter than direct-drive)

- Compact Size: Smaller diameter (easier installation, better clearance)

- Handling Impact: Minimal (low unsprung weight)

- Portability: Manageable for wheel changes, transport

Excellent Low-Speed Torque:

Gear reduction creates strong low-speed performance:

- Hills from standstill conquered confidently

- Traffic light acceleration excellent

- Loaded cargo starts smooth powerful

- Technical slow-speed riding capable

- Natural power delivery all speeds

Freewheeling Capability:

Motors disengage when not powered:

- Pedaling without assist feels natural (no drag)

- Coasting efficient (no motor resistance)

- Battery conservation possible (manual pedaling practical)

- Mechanical failure allows continued riding

- Traditional cycling feel preserved

Quiet Operation:

Nylon gears reduce noise:

- Operating volume minimal (conversation possible)

- Urban environments unobtrusive

- Trail riding discreet

- Mechanical whine absent

- Professional quiet performance

Geared Hub Motor Limitations

Power Ceiling Constraints:

Internal gears limit maximum power:

- Practical Maximum: 750W sustained (1000W peak)

- Beyond 750W: Gear durability concerns increase

- High Power Needs: Direct-drive better choice

- Design Limitation: Physics constraints unavoidable

Gear Wear Over Time:

Moving internal parts experience wear:

- Nylon Gears: Eventual wear (typically 10,000-20,000km)

- Maintenance: Difficult (often sealed units)

- Lifespan: Generally adequate (years of service typical)

- Replacement: Entire motor typically (not individual gears)

Efficiency Limitations Higher Speeds:

Gear multiplication optimized for torque, not top speed:

- Efficiency Drop: Noticeable above 40 km/h

- Top Speed: Typically limited 35-45 km/h efficient operation

- High-Speed Riding: Direct-drive superior

- Design Trade-off: Torque prioritized over speed

Direct-Drive Hub Motors Explained

How Direct-Drive Motors Work

No Internal Gearing:

Direct-drive motors contain the wheel rim within the motor itself—motor rotation directly equals wheel rotation with no intermediate gearing, requiring larger diameter motors with more windings to generate adequate torque at low wheel speeds.

Key Components:

- Large diameter stator (increases torque)

- High winding count (magnetic field strength)

- No internal gears (direct wheel drive)

- Sealed construction (weather resistance)

- Heavy-duty bearings (load capacity)

Operating Principle:

Motor rotation = wheel rotation directly → No gear reduction → Requires larger motor for adequate torque → High efficiency at speed → Regenerative braking possible → Simple robust construction

Direct-Drive Hub Motor Advantages

High Power Capability:

No gears enables extreme power:

- Power Range: 1000W-4000W systems available

- No Gear Stress: Direct drive eliminates fragile internal components

- Extreme Performance: Motorcycle-like capabilities possible

- Power Ceiling: Essentially unlimited (frame becomes limiting factor)

- High-Speed Riding: Efficient 50-80+ km/h

Superior High-Speed Efficiency:

Large motor optimized for speed:

- Efficiency Peak: 45-65 km/h range (vs 25-40 km/h geared)

- Sustained High Speed: Comfortable efficient

- Long-Distance Touring: Highway-speed capability

- Performance Applications: Race, speed priority

- Energy Conversion: Excellent high-RPM efficiency

Maximum Durability:

Simple construction means longevity:

- No Wearing Parts: No internal gears degrading

- Sealed Construction: Complete weather protection

- Lifespan: Often outlasts bicycle frame (decades possible)

- Maintenance-Free: Essentially zero upkeep required

- Reliability: Proven extreme durability

Regenerative Braking Possible:

Motor can act as generator:

- Energy Recovery: Downhill or braking recaptures energy

- Battery Extension: 5-15% range increase typical

- Brake Wear Reduction: Mechanical brakes supplemented

- Heat Dissipation: Motor acts as brake (descents)

- Efficiency Advantage: Unique to direct-drive

Direct-Drive Hub Motor Limitations

Heavy Weight:

No gear reduction requires larger motors:

- Weight Range: 5-8kg typical (vs 2.7-4.5kg geared)

- Handling Impact: Noticeable unsprung weight

- Wheel Changes: Heavier, more cumbersome

- Portability: Challenging (significant mass)

Poor Low-Speed Torque:

Direct drive lacks gear multiplication:

- Hill Starts: Challenging (motor inefficient low RPM)

- Heavy Loads: Struggle low speeds

- Traffic Light Stops: Slow acceleration

- Technical Riding: Not ideal

- Requires Power: 1000W+ needed adequate low-speed torque

No Freewheeling:

Motor always connected to wheel:

- Cogging: Magnetic drag present (motor resistance felt)

- Pedaling Unpowered: Noticeably harder

- Coasting Resistance: Energy waste

- Mechanical Failure: Wheel difficult to turn (tow required)

- Traditional Feel: Lost (always motor engagement)

Noise at Low Speeds:

Large motors hum:

- Low-Speed Operation: Audible hum/whine

- High-Speed: Quieter (efficient operation)

- Urban Riding: More noticeable

- Trail Use: Less discreet

- Noise Level: Moderate (not excessive but present)

Geared vs Direct-Drive Comprehensive Comparison

|

Factor |

Geared Hub Motor |

Direct-Drive Hub Motor |

Winner |

|

Weight |

2.7-4.5kg |

5-8kg |

Geared (40-50% lighter) |

|

Low-Speed Torque |

Excellent (gear multiplication) |

Poor (requires high power) |

Geared |

|

High-Speed Efficiency |

Moderate (35-45 km/h) |

Excellent (50-80+ km/h) |

Direct-Drive |

|

Maximum Power |

750W practical limit |

4000W+ possible |

Direct-Drive |

|

Noise Level |

Quiet (nylon gears) |

Moderate hum |

Geared |

|

Freewheeling |

Yes (disengages) |

No (always engaged) |

Geared |

|

Durability |

Good (gear wear eventual) |

Excellent (no wear parts) |

Direct-Drive |

|

Hill Climbing |

Excellent (low-speed torque) |

Requires high power |

Geared (efficiency) |

|

Flat Terrain Speed |

Adequate (to 40 km/h) |

Superior (50-80 km/h) |

Direct-Drive |

|

Regenerative Braking |

Not possible |

Possible (5-15% range gain) |

Direct-Drive |

|

Installation Difficulty |

Easy (lighter weight) |

Moderate (heavy weight) |

Geared |

|

Maintenance |

Minimal (eventual gear wear) |

Zero (no wear parts) |

Direct-Drive |

|

Best Applications |

Hills, urban, all-around |

High-speed, flat, power |

Application-dependent |

Kirbebike Systems Explained

Geared Hub Motors: 250W-750W Range

Front Wheel Geared Systems:

36V 250W and 48V 250W:

- Motor: 2.7kg lightweight brushless geared

- Speed: 25-35 km/h (legal compliance)

- Range: 30-70km depending on battery

- Application: Urban flat commuting, legal compliance

- Advantages: Lightest option, simple installation

Rear Wheel Geared Systems:

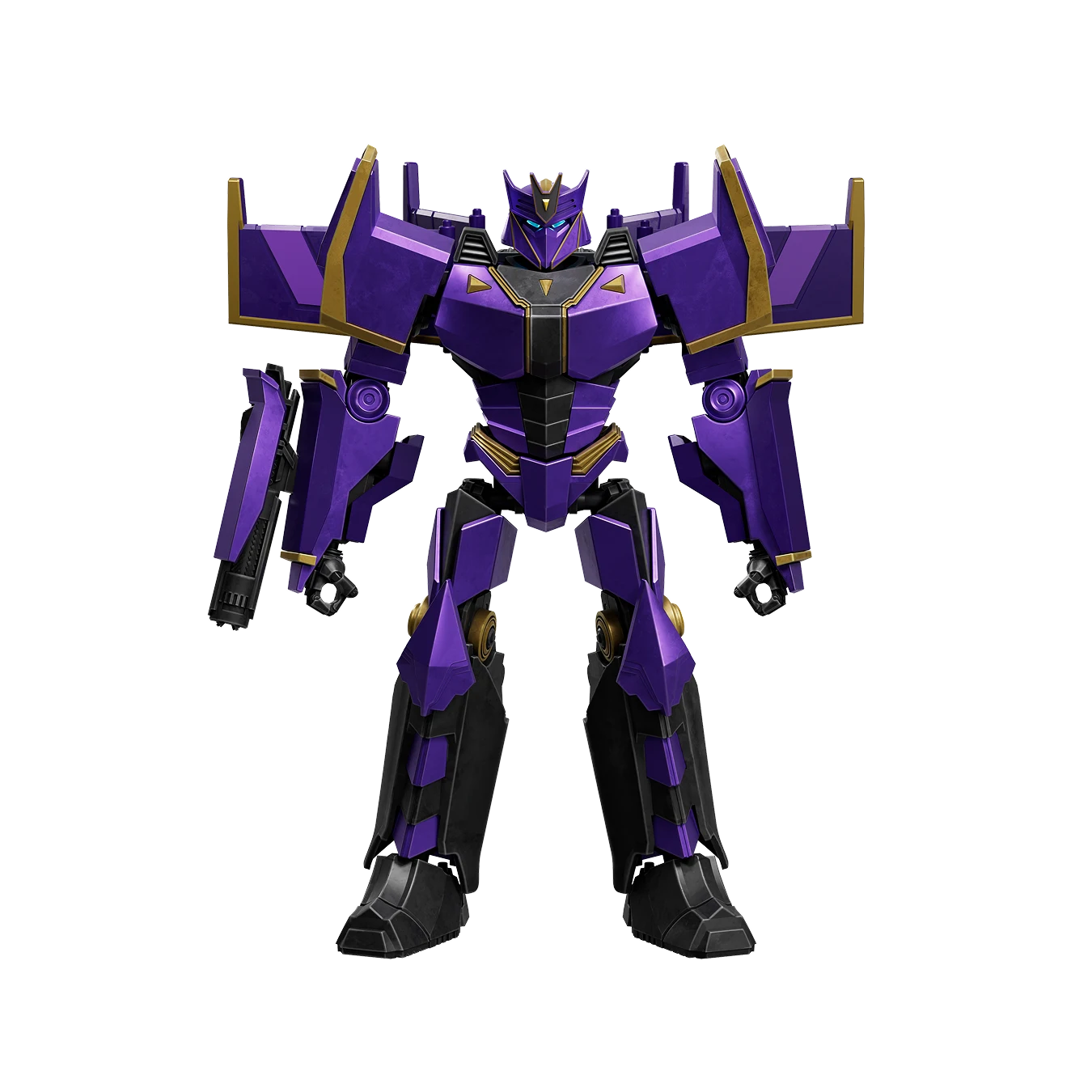

500W-750W SHENGYI:

- Motor: 4.5kg brushless geared (SHENGYI brand proven)

- Speed: 35-40 km/h efficient operation

- Torque: Excellent low-speed performance

- Range: 40-60km typical

- Application: Hills, all-around use, most popular

- Battery: 36V 13Ah to 48V 16Ah options

Direct-Drive Hub Motors: 1000W-4000W Range

High-Power Direct-Drive:

52V 2000W MTX:

- Motor: 5.1-5.3kg direct-drive

- Speed: 50-60 km/h

- Range: 40-60km

- Application: Serious performance

- Battery: 52V 20-30Ah

Extreme Power Direct-Drive:

72V 4000W System:

- Motor: 6.8kg heavy-duty direct-drive

- Speed: 75-85+ km/h

- Range: 40-80km

- Application: Maximum capability, private property only

- Battery: 72V 20Ah

Application-Based Selection Guide

Choose Geared Hub Motor For:

Urban Commuting Priority:

✓ Stop-and-go traffic (excellent low-speed torque) ✓ Hills moderate (gear multiplication advantage) ✓ Weight concerns (2.7-4.5kg manageable) ✓ Natural cycling feel (freewheeling important) ✓ Quiet operation valued (urban discretion) ✓ Legal compliance needed (250W available) ✓ All-around versatility (most situations capable)

Typical Rider: Daily commuter, 10-25km routes, mixed terrain, values lightweight natural feel, hills occasional to moderate, 25-40 km/h speeds adequate

Choose Direct-Drive Hub Motor For:

Performance and Speed Priority:

✓ High-speed riding regular (50-80+ km/h capability) ✓ Flat long-distance (efficiency advantage high speeds) ✓ Maximum power wanted (1000-4000W available) ✓ Extreme durability priority (decades lifespan) ✓ Regenerative braking valued (range extension) ✓ Zero maintenance desired (no wear parts) ✓ Power over weight (5-8kg acceptable)

Typical Rider: Performance enthusiast, flat terrain or high-power hills, speed priority, 30+ km commutes, 45-80 km/h speeds, maximum capability valued

Real-World Performance Comparisons

18-Month Results:

- Low-speed traffic performance excellent

- Hills conquered confidently (gear advantage)

- 4.5kg weight hardly noticed

- Freewheeling appreciated unpowered riding

- Quiet operation valued

- Zero maintenance required

- Battery range 45-50km consistent

- Completely satisfied

Key Insight: "Geared hub perfect urban application—low-speed torque, lightweight, quiet, natural feel exactly what commuting needs."

Direct-Drive Success: Speed Enthusiast

12-Month Results:

- High-speed efficiency excellent (55-60 km/h comfortable)

- Flat terrain advantage clear

- Regenerative braking extended range 10%

- Durability confidence absolute

- 5.3kg weight acceptable trade-off

- Low-speed torque adequate (high power compensates)

- Completely satisfied performance

Key Insight: "Direct-drive high-speed efficiency, power, and durability perfect for performance-focused flat-terrain high-speed commuting."

Technical Insights

Why Geared Wins Low-Speed Efficiency

Gear Multiplication Physics:

Small motor at 3500 RPM → 5:1 gear reduction → 700 RPM wheel speed → Optimal motor efficiency maintained → Low-speed torque multiplied → Smaller lighter motor achieves adequate performance

Direct-Drive Low-Speed Problem:

Large motor at 700 RPM directly → Far below optimal motor RPM → Inefficient operation → Excessive heat generation → Requires much larger motor or higher power → Weight penalty or performance compromise

Why Direct-Drive Wins High-Speed

Direct Connection Advantage:

At 50-60 km/h wheel speed, direct-drive motors operate at optimal internal RPM (efficient magnetic field interaction), while geared motors' internal motors spin excessively fast (heat, efficiency loss), creating geared hub speed ceiling and direct-drive high-speed efficiency advantage.

Installation and Maintenance Differences

Geared Hub Installation

Simpler Setup:

- Lighter weight (easier handling)

- Standard wheel installation

- No special considerations

- 20-25 minutes typical

- Manageable single-person

Direct-Drive Installation

Weight Management:

- Heavy motor (5-8kg)

- Two-person helpful

- Torque arms mandatory high power

- 25-30 minutes typical

- Careful positioning

Long-Term Maintenance

Geared: Minimal, eventual gear wear (10,000-20,000km), usually full motor replacement

Direct-Drive: Essentially zero, no wearing parts, decades lifespan

Making Your Choice

Geared hub motors (250W-750W, 2.7-4.5kg) excel for urban commuting, moderate hills, all-around versatility, natural cycling feel, and weight-conscious riders through superior low-speed torque, freewheeling capability, quiet operation, and lightweight construction making them ideal for typical e-bike conversion applications—while direct-drive hub motors (1000W-4000W, 5-8kg) serve performance-focused riders.

Most riders find geared hub motors like the 500-750W SHENGYI systems provide optimal balance for daily cycling needs, while performance enthusiasts and speed-focused riders benefit from direct-drive technology's high-power high-speed capabilities. Explore the complete electric bike kit battery range including both geared and direct-drive options with detailed specifications, application guidance, and expert support ensuring your conversion matches motor technology to specific riding requirements delivering optimal satisfaction.

Frequently Asked Questions

What's the difference between geared and direct-drive hub motors?

Geared hub motors contain internal planetary gears enabling small lightweight motors (2.7-4.5kg) delivering excellent low-speed torque through gear multiplication, freewheeling when unpowered, quiet operation, but limited to 750W maximum.

Which hub motor type is better for hills?

Geared hub motors superior for moderate hills through gear multiplication creating excellent low-speed torque (500-750W geared outperforms 1000W direct-drive efficiency climbing). However.

Why are direct-drive hub motors heavier than geared?

Direct-drive motors connect wheel rotation directly to motor (no gears), requiring large diameter motors with extensive windings generating adequate torque at low wheel speeds.

Do geared hub motors wear out faster than direct-drive?

Eventually yes—geared motors contain nylon internal gears experiencing wear (typically 10,000-20,000km lifespan), though usually adequate for years of service before replacement needed.

Can I use regenerative braking with geared hub motor?

No—regenerative braking requires direct motor-to-wheel connection enabling motor to act as generator during braking. Geared motors' internal freewheeling mechanism (enabling coasting without drag).