The journey from a digital concept to a physical masterpiece on your shelf is a marvel of modern manufacturing. If you have ever held a high-quality model kit and wondered about the precision behind its joints or the vibrant finish of its armor, you are tapping into a world of advanced robotics engineering.

Understanding how are transformers toys made reveals the dedication to quality that separates a standard plaything from a premium collectible. Today, we go behind the scenes to explore the design, molding, and assembly processes that bring your favorite Cybertronian heroes to life.

Phase 1: From Concept Art to 3D Blueprints

The process begins long before any plastic is cast. Professional designers start with detailed concept art, often drawing inspiration from iconic media like the Transformers ONE movie or classic heritage designs.

Digital Engineering

Once the visual style is established, engineers use advanced Computer-Aided Design (CAD) software to create a digital 3D model. This is where the "magic" happens. Designers must account for:

- Point of Articulation: Modern kits often feature 20 or more movable joints.

- Clearance: Every limb must move freely without scraping against other parts.

- Structural Integrity: Even the smallest products must be durable enough to hold a pose.

Phase 2: Precision Injection Molding

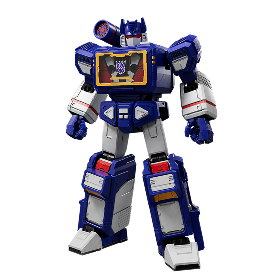

The most critical step in answering how are transformers toys made is injection molding. This industrial process ensures that every piece in a model kit is identical and fits perfectly.

The Use of High-Quality Materials

Leading manufacturers use premium ABS plastic. This material is chosen for its strength, smooth surface, and ability to hold fine detail. Molten plastic is injected into steel molds at high pressure. Once cooled, the parts emerge on a "sprue" or frame, ready to be organized into sets.

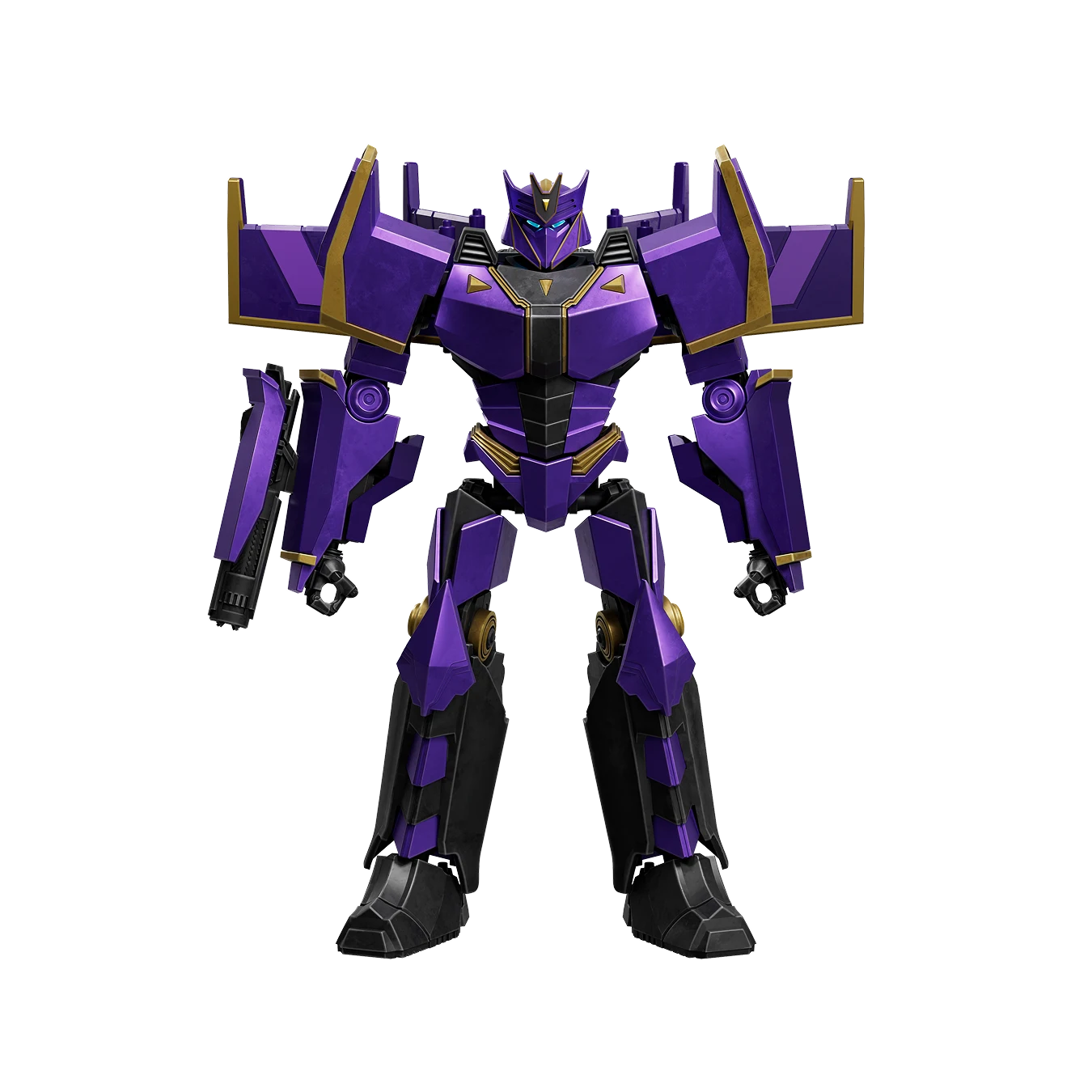

Tooling and Precision

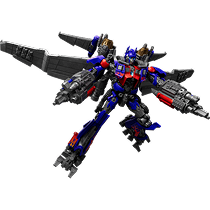

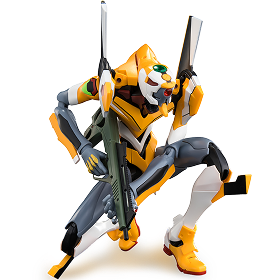

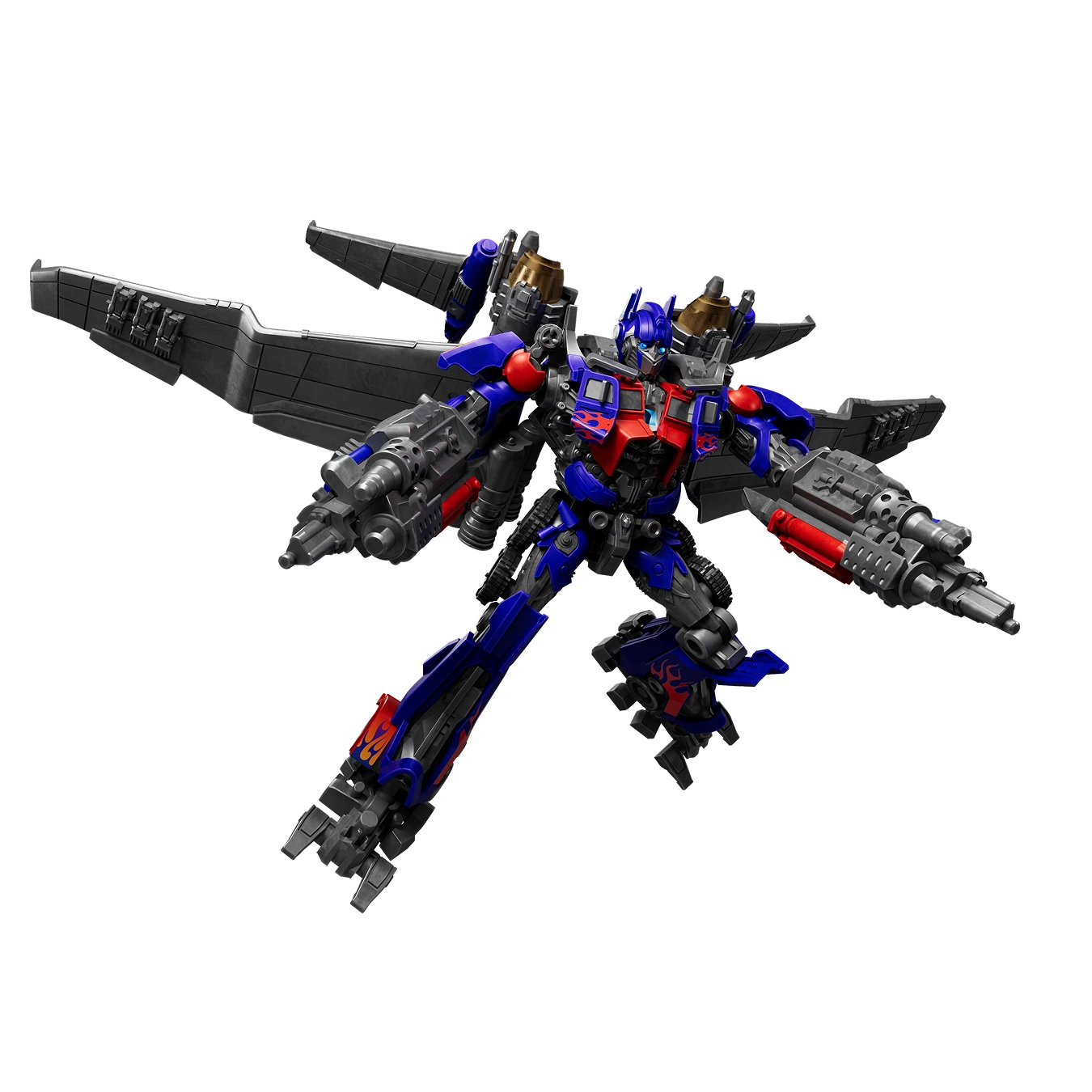

The steel molds, often called "tooling," are engraved with microscopic precision. This allows for the intricate mechanical lines and textures you see on the armor plates of Galaxy Version products.

Phase 3: Advanced Finishing and Electronics

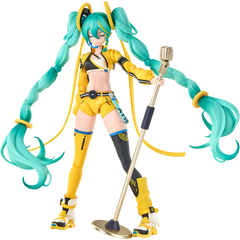

Unlike older toys that relied on stickers, modern model kits use advanced painting and molding techniques.

- Color Injection: Parts are often molded in their final colors, so there is no paint to chip or peel.

- Light-Up Features: Many premium kits now include motion-sensitive LED modules. These are engineered to fit inside the head or chest to provide glowing eyes or power cores without the need for complex wiring by the user.

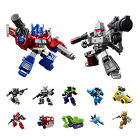

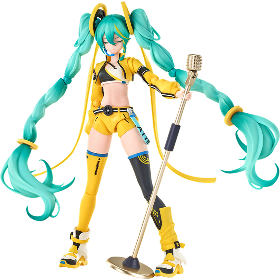

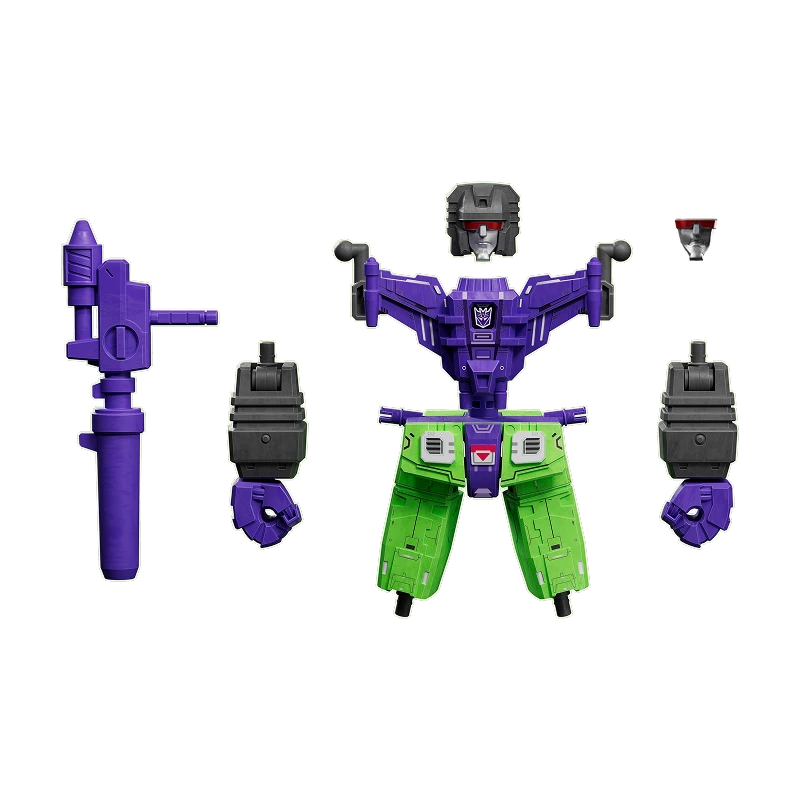

Phase 4: The Snap-Fit Assembly Experience

A common question from new hobbyists is: do they still make transformers toys that are easy to put together? The answer is a resounding yes. The industry has shifted toward "snap-fit" technology.

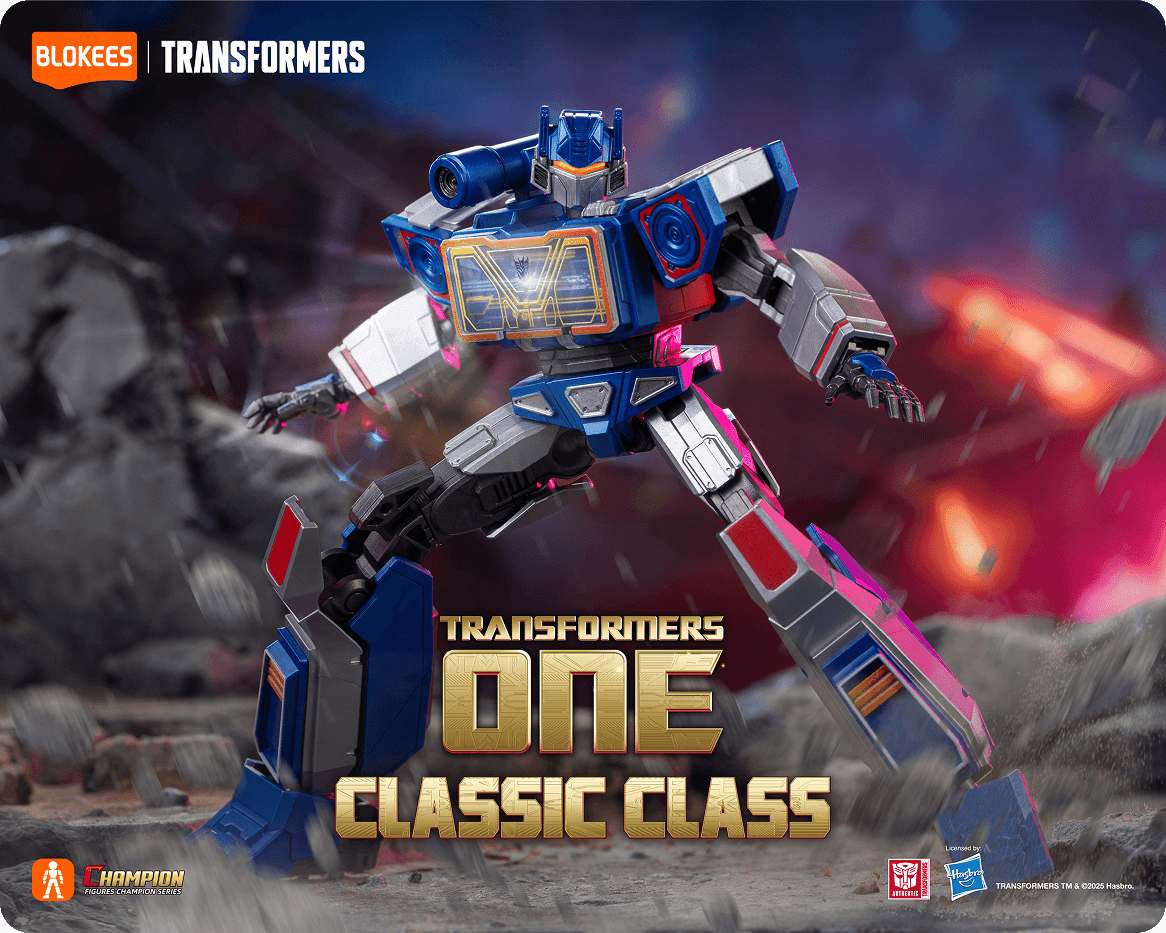

This engineering feat means every tab and slot is calculated to a fraction of a millimeter. When you assemble a Classic Class set, the pieces click together securely. No glue, screws, or specialized tools are required, making the assembly experience accessible for everyone from beginners to veteran collectors.

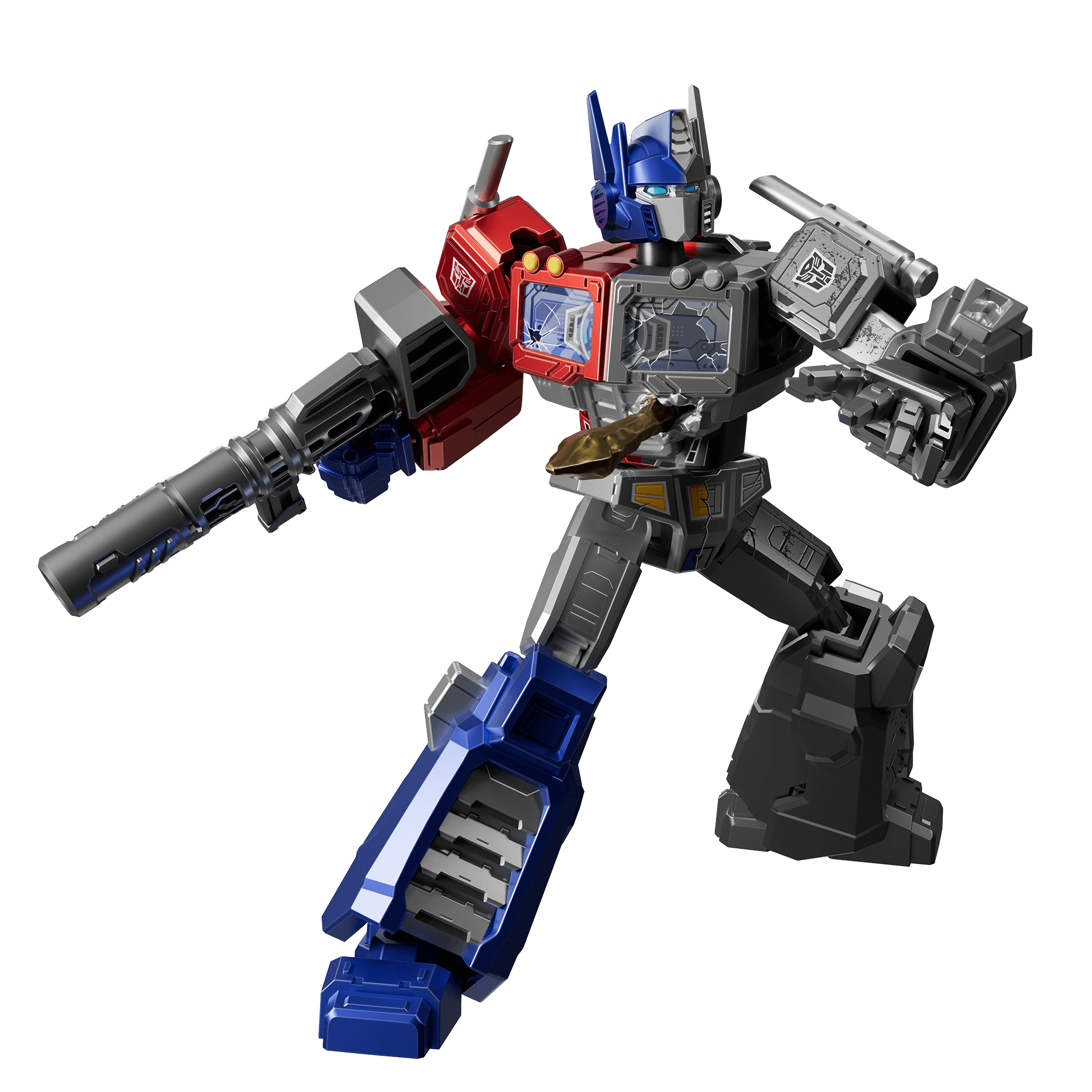

The Evolution of Prototype Testing

Before a model kit reaches the mass-production stage, it must pass through rigorous prototyping. In the past, this involved hand-carved clay models, but today, engineers utilize high-resolution 3D printing. These physical prototypes allow the design team to test the "hand-feel" of the toys and ensure that the joints can support the weight of the limbs in various poses.

This stage is crucial for ensuring that the Action Edition products maintain their balance. Designers will often adjust the thickness of a peg or the depth of a socket by fractions of a millimeter based on these tests. This level of scrutiny ensures that when you begin your assembly experience, every piece fits exactly as intended, providing a sense of premium quality.

Sustainable Manufacturing and Material Safety

A significant part of the modern manufacturing conversation is the shift toward eco-friendly practices. When considering how are transformers toys made easy for a global market, manufacturers also focus on the safety and sustainability of the materials. Most contemporary model kits are produced in facilities that prioritize the reduction of waste during the injection molding process.

The ABS plastic used is not only durable but also recyclable. Furthermore, the move away from adhesives and toward snap-fit designs reduces the chemical footprint of the hobby. For collectors who frequent the Best sellers list, this commitment to quality and safety means that the products are last for generations without degrading, making them a sustainable choice for enthusiasts who care about the environment as much as their collection.

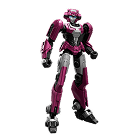

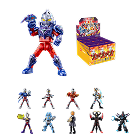

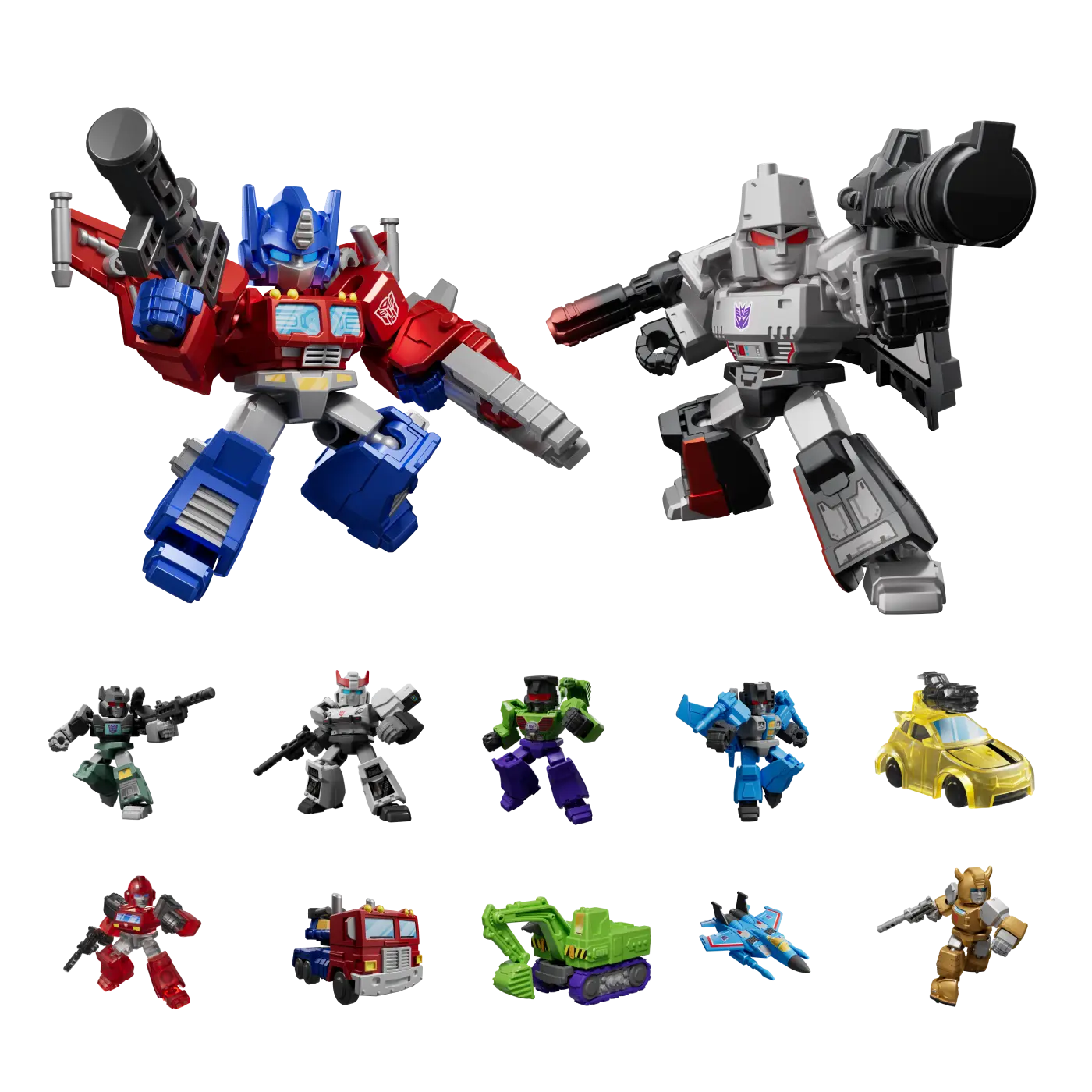

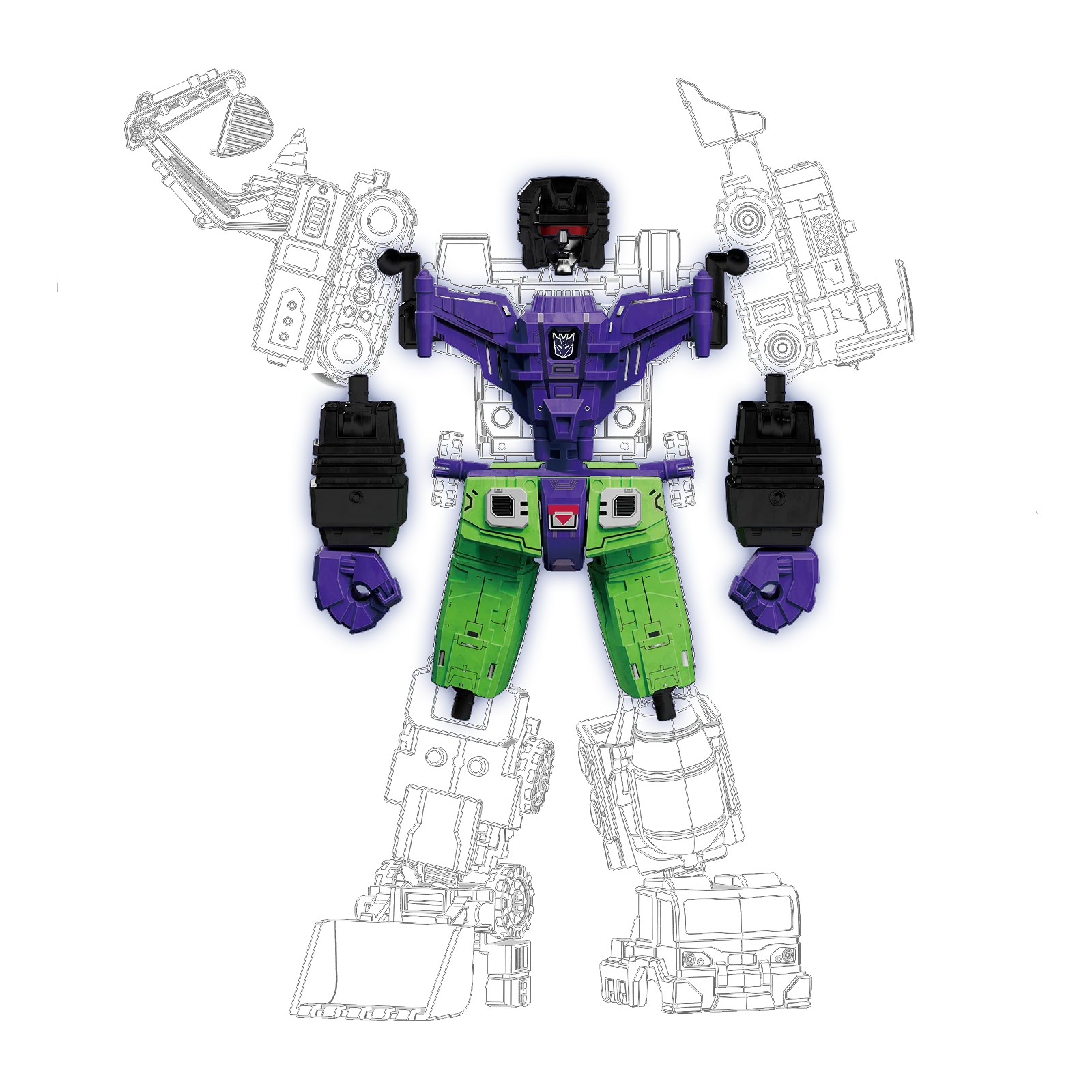

Precision Engineering in Miniature

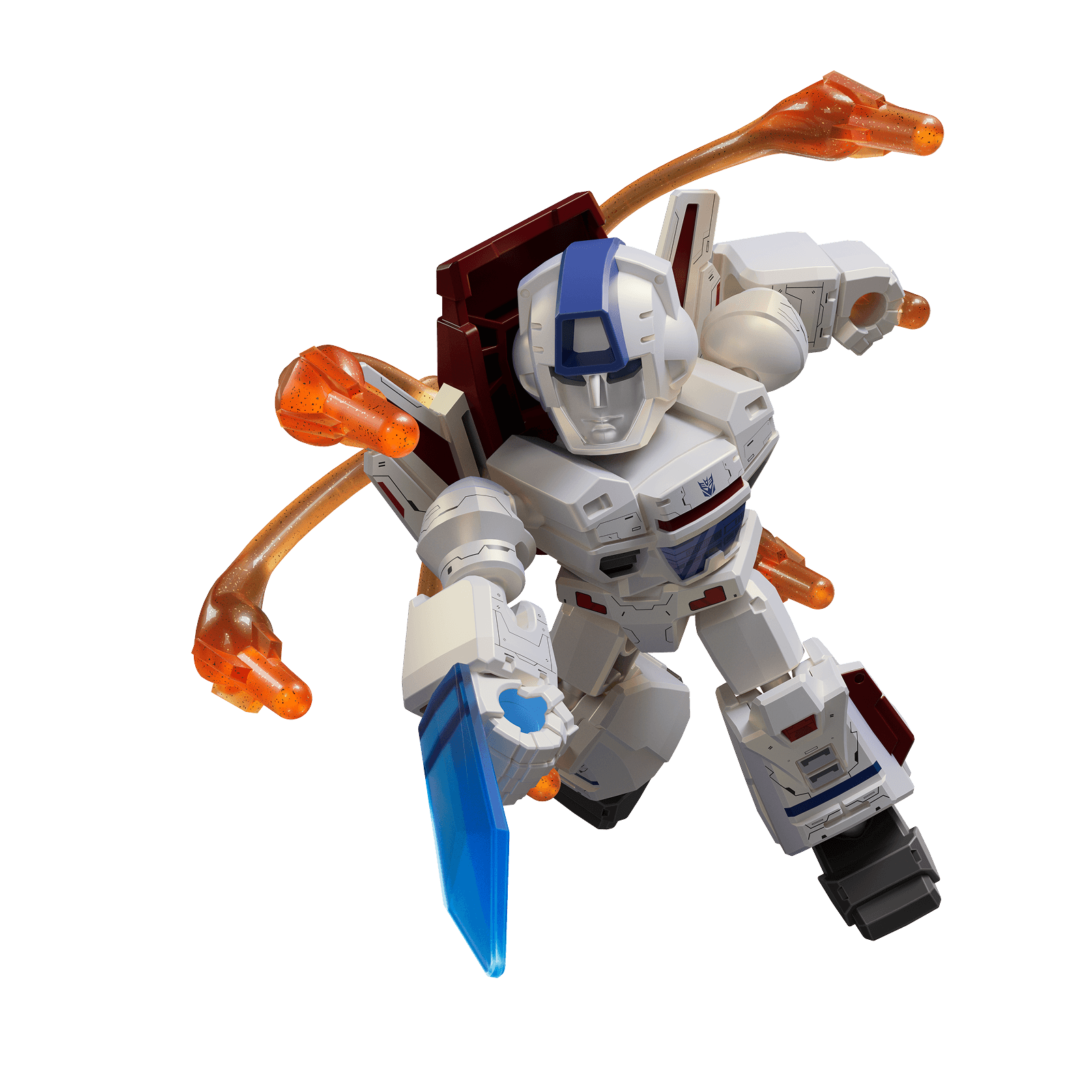

Designing the world's smallest transformers toys presents its own set of unique engineering hurdles. As the scale decreases, the tolerance for error becomes almost zero. Engineers must simplify the internal structures while maintaining the external complexity that fans expect. This is often achieved through "part consolidation," where a single molded piece performs the function that would require three pieces in a larger scale.

In the Defender Version series, for example, the engineering focus is on maximizing the "pose-ability" within a very small footprint. Even at a height of just a few centimeters, these kits often feature ball-jointed necks and pivoting waists. This is a testament to how far manufacturing technology has come, allowing for incredibly detailed and articulated toys that can fit in the palm of your hand.

Why Engineering Matters for Collectors

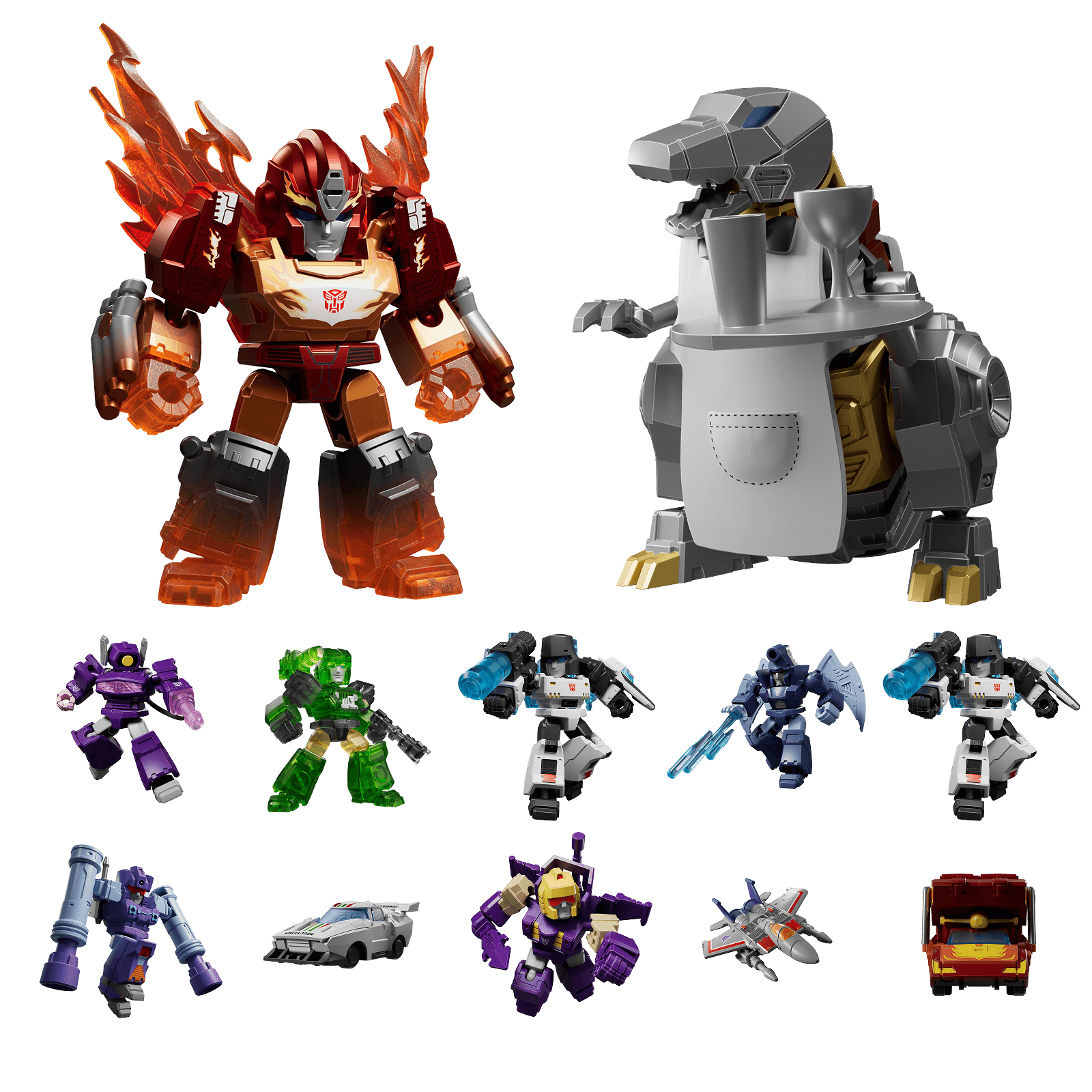

The engineering behind these model kits isn't just about making them look good; it's about how they feel in your hand. High-end toys utilize friction-fit joints that stay tight over time. This allows you to create dynamic battle stances and display your collection with confidence.

Whether you are unboxing a surprise box from the New Arrivals section or assembling a large-scale leader, the engineering ensures that the product remains a centerpiece of your collection for years to come.

Frequently Asked Questions

How are transformers toys designed for movement?

Engineers use 3D modeling to place "ball joints" and "hinge joints" at key points like the neck, shoulders, and knees. This allows for a wide range of motion and realistic posing.

Do they still make transformers toys with metal parts?

While some high-end collector versions might use die-cast materials, most modern model kits favor high-density ABS plastic because it allows for sharper detail and better joint longevity.

How are transformers toys made easy for beginners to assemble?

Manufacturers use "snap-fit" engineering. This means parts are designed to lock together with a simple "click," removing the need for glue, paint, or hobby knives.

Is the plastic used in these kits safe?

Yes, reputable brands use eco-friendly, high-quality ABS plastic that is non-toxic and durable, ensuring the products are safe for display and handling.

How long does it take to design a new model kit?

The process from initial concept art to the final product hitting the shelves can take anywhere from 12 to 24 months, involving multiple rounds of prototyping and testing.

Are these kits painted at the factory?

Most parts are "molded in color," meaning the plastic itself is the correct shade. Any extra details are added using precision pad printing or specialized finishes during the manufacturing phase.